This week:

Crossing the valley of death: China wants to leverage tech innovation to unleash new economic development. But first, it must optimize the transformation of lab research to commercial products.

Weekly Links: Generic drug manufacturing, 155mm shells, the contest Arctic.

The innovation valley of death

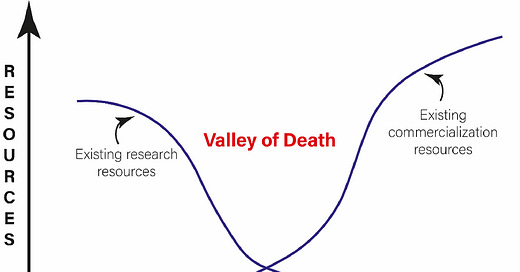

You have likely heard of the “valley of death.” It refers to the early stages of innovation, at the cusp of original scientific research and commercialization. Cresting the valley means successfully going from laboratory to market. Getting stuck there means languishing among the carcasses of other good (and bad) ideas.

China has set a goal of unleashing “new quality productive forces.” To achieve that, technological innovation (in addition to process innovation) will be key. That requires researching and developing new ideas and technologies, both to minimize dependence on foreign know-how and to open up new technological frontiers. Where China has mastered going “from one to 100,” it now wants to make more breakthroughs “from zero to one.”

Doing so requires crossing many valleys of death. And China has a plan to make those valleys more surmountable. It aims to set up numerous government-backed pilot testing platforms targeting strategic sectors, in hopes of giving a state-led boost to the industrialization of scientific research.

It’s hard to tell whether this plan will work out. But putting aside questions of efficacy, there is also value in examining how China intends to increase its manufacturing strength with targeted pilot testing efforts. Plus, scrutinizing which specific technologies Chinese officials are focusing on for pilot tests can tell us how Beijing assesses its technological standing and prospects.

Giant laboratories, mini production lines

In January, the Chinese government published policy measures for developing pilot testing in the manufacturing industry. The document explains why pilot testing is important:

“Pilot testing is a transitional test that transforms new products in the trial production stage into the production process. It is a key link in the industrialization of scientific and technological achievements, an organic part of the manufacturing innovation system and an important support for the modern industrial system.”

Pilot testing platforms, the state-owned Science and Technology Daily explained, are “bridges connecting laboratories and application fields, and a ship to help enterprises cross the ‘valley of death.’” Or as China’s leading military electronics manufacturer put it, they are “an enlarged laboratories or shrunken production lines.”

The January policy document lays out high-level directives for building a national pilot testing system. The government is to support leading companies in key industries to establish pilot production lines. The pilot testing platforms are to be connected to China’s industrial internet, linked up with the Internet of Things and 5G technologies, and supported by machine vision and industrial AI — all to optimize process efficiency “through comprehensive perception, real-time analysis, scientific decision-making, and precise execution.”

Chengdu, pilot testing central

On the ground, numerous pilot testing sites are already being set up and put into operation.

Chengdu hopes to be the go-to place for manufacturing pilot runs. The city in Sichuan province has proposed setting up China’s first ever “pilot platform construction fund,” to a tune of five billion yuan. And it has set some clear goals: 100 key pilot testing platforms, 500 products launched onto the market, and 100 “innovation companies” incubated — all by 2025.

The city is also opening its check books. Pilot platforms for leading and emerging industries like “power semiconductors, biomedicine, medical devices, in-vehicle intelligence, smart sensor chips, and advanced ceramic materials” can receive up to 50 million yuan each in state funding, and specific pilot testing projects can get up to 10 million yuan each.

As of March, Chengdu already has pilot testing platforms and “proof of concept centers” constructed, according to a published list. Many of those platforms are in fields where China urgently wants to make breakthroughs, including biotech and biopharma, intelligent hardware, power semiconductors, optical materials and devices, and aviation equipment.

And it’s not just Chengdu. Over in Wuhan’s Optics Valley, a high tech industry zone focused on optoelectronics and other advanced information technologies, three key pilot testing platforms have already been set up targeting laser processing, drug development, and new display technology.

Testing, testing, 1-2-3

China has had great success leveraging process knowledge to scale and commercialize original research done elsewhere. Solar panels, lithium-ion batteries, and high-speed railways are just three examples. Now it wants to scale greater heights by ramping up basic research, industrializing that knowledge, and bringing cutting-edge products to global markets.

But first, it must navigate numerous innovation valleys of death. Research conducted by the China High-Tech Industrialization Association, and cited by a government official, suggests that the success rate of industrializing laboratory research is only 30% without pilot testing, but rises to as high as over 80% with a pilot run.

That may well be an optimistic outlook. But if it works, one could imagine China turbocharging its innovation and iteration processes — and perhaps flipping the script on foreign competitors on whom it currently depends on for key technologies.

Weekly Links

🖇️ Can US manufacturing of generics be reinvigorated? “The generic drug business has become a hostile environment for American companies. Prices for the often critical medicines have dropped so low that it has become difficult for US manufacturers to compete with companies overseas,” reports Liz Essley Whyte. (WSJ)

🖇️ A crash course in 155mm artillery shell production. I recently learned of Rob L’Hereux’s excellent newsletter, about material progress. In this February 2024 post, he explains in detail the materials and mechanics of 155mm shells, their supply chain, bottlenecks contributing to the current shortage, and what can be done to address it. (Happy Future)

🖇️ The contested Arctic. Coinciding with the US Department of Defense’s new Arctic strategy, Didi Kirsten Tatlow has a piece on China’s expanding Arctic ambitions, as manifested in part through dual-use research in the polar region carried out by units with close ties to the People’s Liberation Army. (DoD, Newsweek)

China has learned that heavy integration is the way to go. Take for example BYD, from electric vehicles to batteries to semiconductors. The end goal is never lost from sight.

Nice piece @Mary Hui. China’s advantage is scale and this is underappreciated in the West. The synergy between production and innovation has been forgotten.

Building a few prototypes of something is relatively easy, mass production is an order of magnitude more difficult. But if one can produce something in mass, one can improve it rapidly and leap ahead of everyone else.

This is what China has done with electric buses. While the rest of the world fiddles with a few dozen buggy buses and complains about their reliability, China has been producing them in bulk for 10 years. During that production, the faults and flaws are identified and rectified.

China is doing the same with EVs and soon computer chips. The very act of producing them enables innovation to speed ahead.